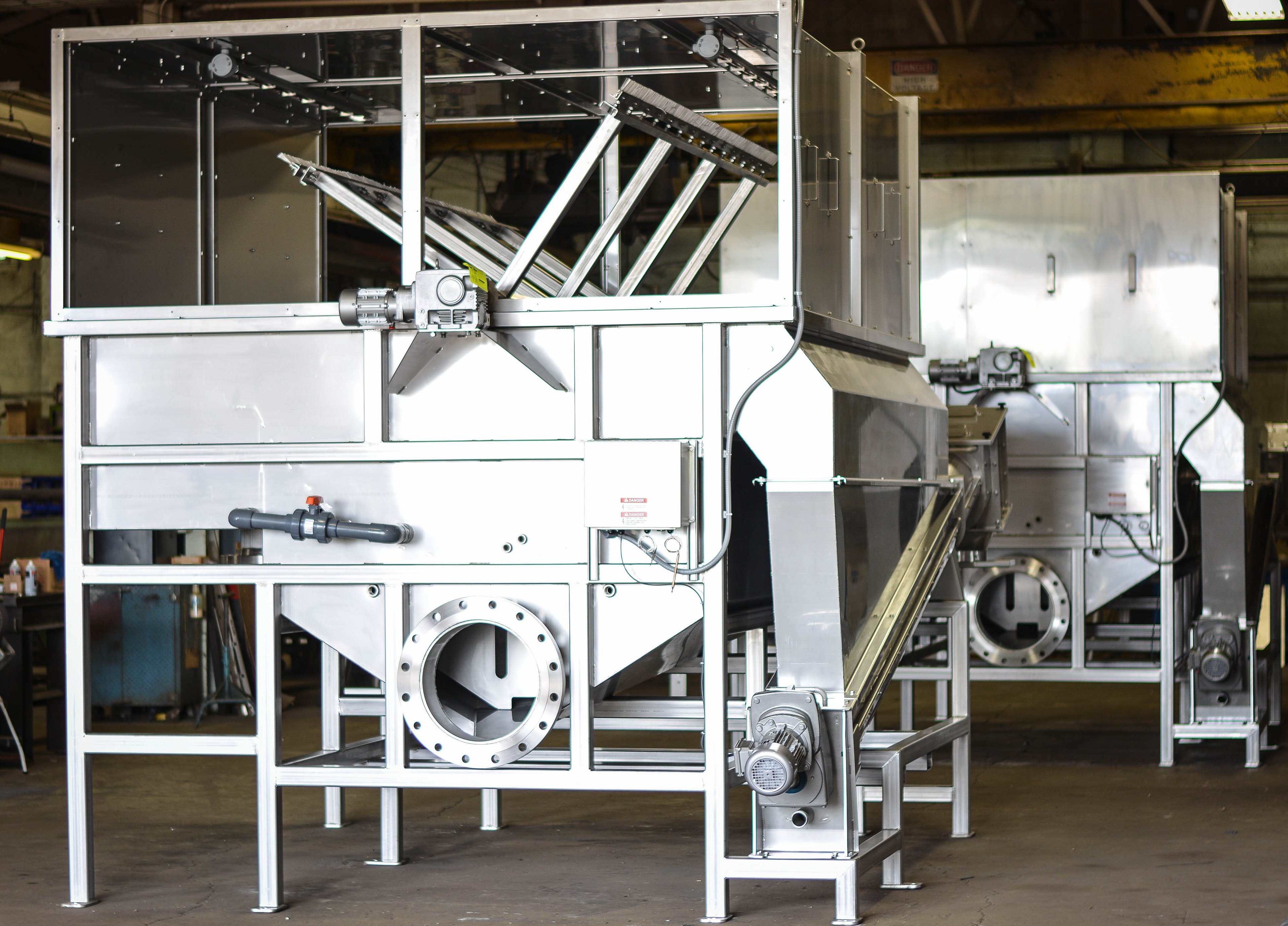

Rotary Brush Screen

Perfect for Membrane Bioreactors (MBR) and the headworks of WWTP

It is a good piece of equipment, works well and is low maintenance.

- George, Green Valley Packing, Claysville, PA

The Or-Tec Rotary Brush screen is manufactured from stainless steel and is designed to remove fibers, hair and other foreign objects from a waste stream. It uses a static stainless steel perforated semi cylindrical screen bed for this purpose. This bed is continually cleaned by a stainless steel armature with brushes. The brushes are selected based on the particular waste and gently sweep the screen bed. This action cleans the screen bed but puts no pressure on the screen bed. This prevents the distortion and wear that can occur on other types of perforated fine screens. The brushes are cleaned by a stainless steel scraper blade and discharged outside of the machine.

Or-Tec Rotary Screen brushes have approximately 1 inch of adjustment so even in situations with aggressive or abrasive wastes the brushes last many years.

The Or-Tec Rotary Brush Screen options include:

- Compactors

- Platforms and Walkways

- Endless Bags

- Heat Tracing

- Hoppers or Filtrate Tanks

- Liquid Level Sensors

- Control Panels

- Explosion Proof Environments (Class 1, Division 1)

Applications:

- MBR (Membrane Bioreactors)

- WWTP Headworks

- Food Processing and Packaging

- Paper Mills

- Industrial Materials